Understand Scrap Metal Types: Iron and Steel

Wondering how to deal with leftover scrap from construction sites, outdated appliances, or wrecked vehicles? Instead of tossing them aside, why not bring them to C&D? Before you make the trip, let’s explore some key tips for recycling iron and steel.

At C&D, we simplify the process of scrapping iron and steel. We’re here to take those unwanted materials off your hands while putting some extra cash in your pocket. Plus, recycling iron and steel is an excellent way to support a healthier planet. Interested in learning how to evaluate your scrap, get it ready for recycling, and maximize your returns? Read on!

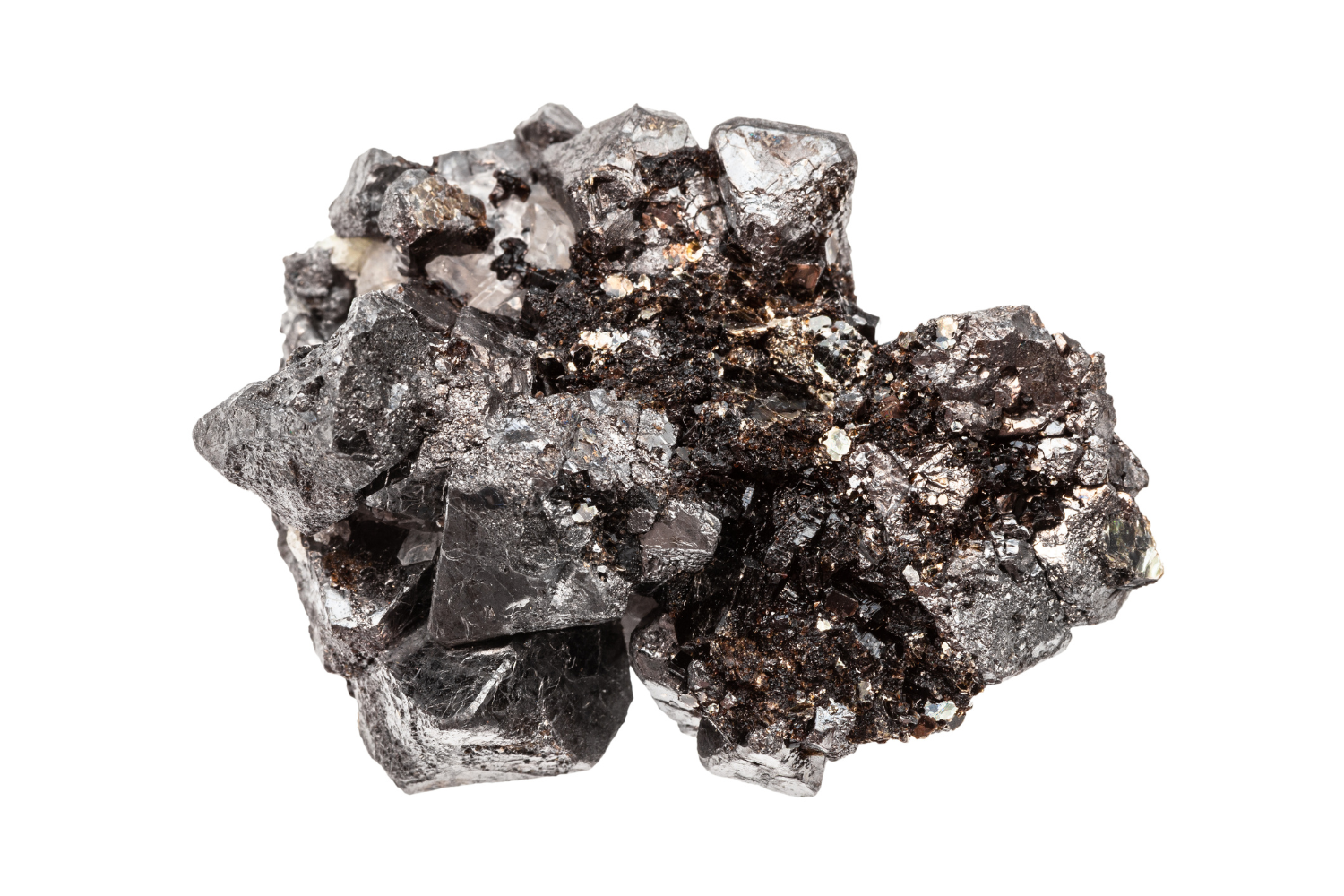

Understanding Scrap Iron and Steel

What exactly do we mean by scrap iron and steel? Simply put, it includes any iron or steel materials that you no longer need, usually from things like consumer goods, construction sites, or old cars. You’ll often find the most common types of scrap iron and steel in discarded appliances or structural steel from buildings. The great thing is that these materials are highly recyclable, which means they can be processed quickly and turned into something new, making them really valuable!

But there are many sources of iron and steel scrap, including:

- Structural Steel: This includes beams, columns, and other components from buildings and bridges—highly valuable when recycled.

- Automotive Steel: Think of parts from old cars, such as frames, doors, and engine components. These materials are recyclable and contribute to reducing waste.

- Household Steel: Appliances like refrigerators, washing machines, and stoves can find new life through recycling.

- Miscellaneous Steel: Scrap from fences, pipes, and industrial equipment is often overlooked but can be recycled efficiently.

At C&D, we’re committed to helping you recycle your scrap iron and steel responsibly. Whether you’re cleaning out your garage, renovating a space, or managing a construction project, we’re here to partner with you in making recycling easy and effective. Together, we can turn your unwanted iron and steel into a valuable resource for both you and the environment.

What is Steel?

Iron and steel come in various types, each with unique qualities and recycling value. Let’s look at some common types you’re likely to encounter and why they matter in recycling:

- Carbon Steel: This is the most common type of steel, used in everything from construction to automotive applications. It’s known for its strength and durability.

- Stainless Steel: Recognizable for its corrosion resistance, stainless steel is found in appliances, cutlery, and medical instruments. Its recycling value is typically higher due to its alloy content.

- Cast Iron: Commonly used in cookware, pipes, and automotive parts, cast iron has a high recycling value because it can be melted down and repurposed without losing quality.

- Heavy Melting Steel (HMS): This includes scrap metal from heavy machinery and equipment. It’s usually sold as a mix of various steel types.

- Miscellaneous Iron and Steel: This category includes various household and industrial items, such as pipes, rebar, and old furniture—all of which can be recycled.

The Recycling Process of Scrap Iron and Steel

Recycling scrap iron and steel combines hands-on effort with cutting-edge technology, ensuring top-notch recovery and sustainability at every step:

- You Bring It to C&D: Start the process by bringing your iron and steel scrap to our facility. Our friendly team is ready to assist you!

- Initial Inspection and Sorting: We assess the quality and type of your scrap.

- Cleaning and Preparation: Any non-metal attachments or contaminants are removed to enhance the value.

- Shredding and Separation: Larger pieces are shredded to facilitate the separation of different metals and materials.

- Metal Purification and Preparation: The iron and steel are purified to meet industry standards before being sold to manufacturers.

- Repurposing into New Products: The recycled iron and steel are transformed into new products, contributing to a sustainable future and reducing the need for raw materials.

Benefits of Recycling Iron and Steel with C&D

One of the biggest advantages of choosing C&D is how straightforward and hassle-free we make the entire process. From the moment you contact us, we handle everything:

- Simple Assessment and Quote: We provide a quick and accurate assessment of your scrap iron and steel and offer a competitive quote.

- Flexible Scheduling: We work around your schedule to arrange for drop-off or pick-up of your materials.

- Quick & Easy Payout: Get paid fast and on the spot based on the weight of your scrap.

Environmental Advantages of Recycling Iron and Steel

Choosing to recycle your iron and steel with C&D isn’t just a smart financial decision; it also brings big benefits for our planet:

- Resource Conservation: Recycling iron and steel conserves valuable natural resources, significantly reducing the need for new mining and extraction processes. Given that iron and steel are among the most recycled materials worldwide, recycling these metals helps to preserve our natural resources and ensures they remain available for future generations.

- Energy Efficiency: The process of recycling iron and steel uses substantially less energy compared to extracting and refining virgin materials. For example, recycling steel saves about 60% of the energy required to produce new steel from raw materials. This energy efficiency not only lowers production costs but also helps to decrease greenhouse gas emissions, making it a more sustainable choice.

- Reduced Pollution: Properly recycling iron and steel mitigates the release of harmful substances into the environment. By recycling these materials, you lessen the demand for new raw materials, which in turn helps to reduce air and water pollution associated with mining and manufacturing processes.

- Circular Economy Contribution: Recycling iron and steel supports a circular economy, where materials are reused and repurposed rather than discarded. This reduces waste in landfills and encourages sustainable production practices, ultimately leading to a more resilient economy.

By recycling iron and steel, you're contributing to a more sustainable future while also reaping financial rewards!

Before You Bring Us Your Iron and Steel Scrap

A little preparation can significantly enhance your recycling experience. If you have different types of iron and steel—like structural steel, automotive parts, or appliances—separating them before drop-off can speed up the recycling process.

How Steel Scrap Metal Prices Are Set

Ever wondered why scrap metal prices fluctuate? Here’s a quick breakdown of what determines the iron and steel scrap price:

- Type and Quality: The cleaner and purer your metal, the more it’s worth. Quality matters!

- Market Demand: Scrap prices move with the market. If demand for iron and steel is high, prices could rise accordingly.

- Quantity: The more metal you bring in, the better your rate. Bigger hauls often mean better deals.

- Processing Costs: Sorting, cleaning, and transporting scrap take time and resources. While you get paid, these factors also play into the final price.

By following these tips and knowing how pricing works, you’ll be ready to get the most out of your iron and steel recycling!