How CNC Manufacturers Can Profit from Recycling Metal Chips and Shavings

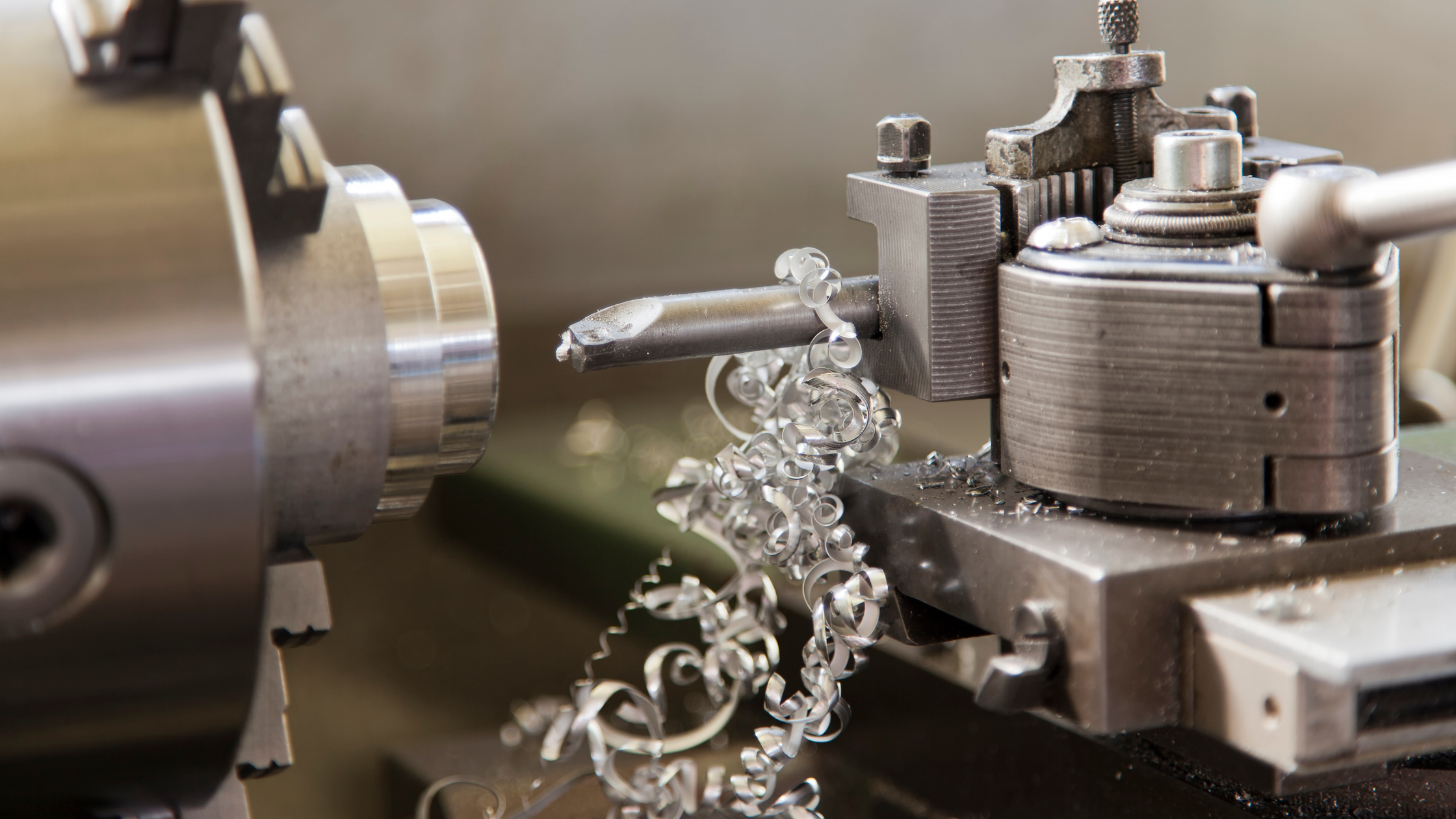

Computer Numerical Control – or CNC – machining is all about precision in manufacturing. It involves computer-guided machinery that expertly cuts and shaves away blocks of materials to make everything from planes and cars, to jewelry, computers and medical instruments.

As any commercial manufacturer knows, the process also generates a lot of scrap. The metal shavings, turnings, and chips, also known as swarf (from the old English for ‘file away’), are the metallic byproducts of CNC machining, but they are much more than leftovers.

Collected metal shavings are often recycled to recover valuable materials, reduce environmental impact — and make a profit. Utilizing a trusted partner for swarf recycling guarantees eco-friendly and responsible waste management in CNC manufacturing.

Harnessing the Value of CNC Metal Shavings and Alloy Steel

CNC machining remnants contain valuable material, including metal shavings, turnings, and chips, sourced from a variety of industrial metals that have real recycling significance.

The CNC shavings contain a number of high-value metals. These include:

- Alloy Steel

- Aluminum Alloy

- Titanium Alloy

- Cast Iron

- Copper Alloy

- Nickel Alloy

- High-temperature Alloys, like Hastelloy

The size and shape of the shavings that can be recycled depend on factors such as the cutting parameters, tool geometry, and the raw metal – or stock – being machined. And while efficient chip control in CNC machining makes for a smooth operation, preventing issues like tool wear, heat buildup, and poor surface finish – many chips are still generated in the process.

Accumulated shavings in a machine can cause issues like overheating, contamination, and potentially be a fire hazard. Conveyors, vacuums, or blowers help with chip removal. The metal shavings can be stored safely in bins, bags, or containers, awaiting recycling.

Steel swarf, as one example, can be repurposed by steel suppliers to create high-grade alloy steel wire rods and bars.

C&D Scrap Metal accepts both the metal shavings and the replaceable cutting tips crucial for the machining operation. These carbide inserts, also known as tips, are made from a combination of carbon and elements such as tungsten, titanium, or tantalum. They exhibit excellent hardness, wear resistance, and heat resistance, making them recycling VIPs.

Why A CNC Recycling Expert Matters

Metal shavings or turnings produced during machining bring potential risks. Freshly cut metal chips can be sharp, or even flammable, requiring careful handling afterward. Improperly disposing of metal swarf harms the environment, threatens ecosystems, and stresses local water treatment facilities.

It’s essential to prioritize the safe recycling of these metals, not only to reduce a company’s environmental footprint and improve how resources are used but also to cultivate a workplace that values social responsibility and exhibits effective governance. This underscores their dedication to ESG principles and sustainable business practices.

Efficient swarf recycling in CNC manufacturing involves careful collection, sorting, and prep. Different metal types are separated, solid pieces distinguished from fine particles, and cutting fluids and chemicals drained or separated.

While in-house swarf management has its challenges, collaboration with metal recycling experts, such as C&D Scrap Metal, offers a safe, practical, and economically viable approach to CNC recycling.

Recycling Opportunities Across CNC Manufacturing

With CNC machines widely used in many industries, there are ample opportunities for recycling across various sectors. CNC automotive, aerospace, healthcare, electronics, oil and gas, defense, tool and die making, custom manufacturing, woodworking, plastics and jewelry are just some examples.

As these industries continue to use CNC, swarf will continue to have immense recycling potential. And keeping these valuable shavings out of landfills is yet another way that industry can innovate by example.

Work with C&D Scrap Metal to Recycle Your Swarf

While shavings are frequently overlooked as a nuisance, they present untapped recycling potential for commercial manufacturers. This is due to the sought-after industrial metals embedded in CNC machining remnants.

Compliance with scrap management guidelines rules is a must to maintain a sustainable and advantageous recycling process. Companies who do this well protect the environment and preserve valuable metals to maximize their economic benefit.

As a reliable partner, C&D Scrap Metal can provide sustainable solutions and competitive pricing. We streamline the recycling process, ensuring both environmental responsibility and financial gains for your business.

Contact C&D for a quote and more on our CNC scrap collection.