What to do with leftover brass from old fixtures, damaged musical instruments like trumpets and saxophones, or brass fittings in electrical components? Bring them to C&D! But before you do, here’s everything you need to know about recycling brass.

At C&D, scrapping brass is easy. We’ll take it off your hands and give you some extra cash. Plus, recycling your unwanted brass items is a great way to help the environment.

Want to know how to evaluate your brass scrap, prep it for recycling, and get top dollar for your materials? Read on!

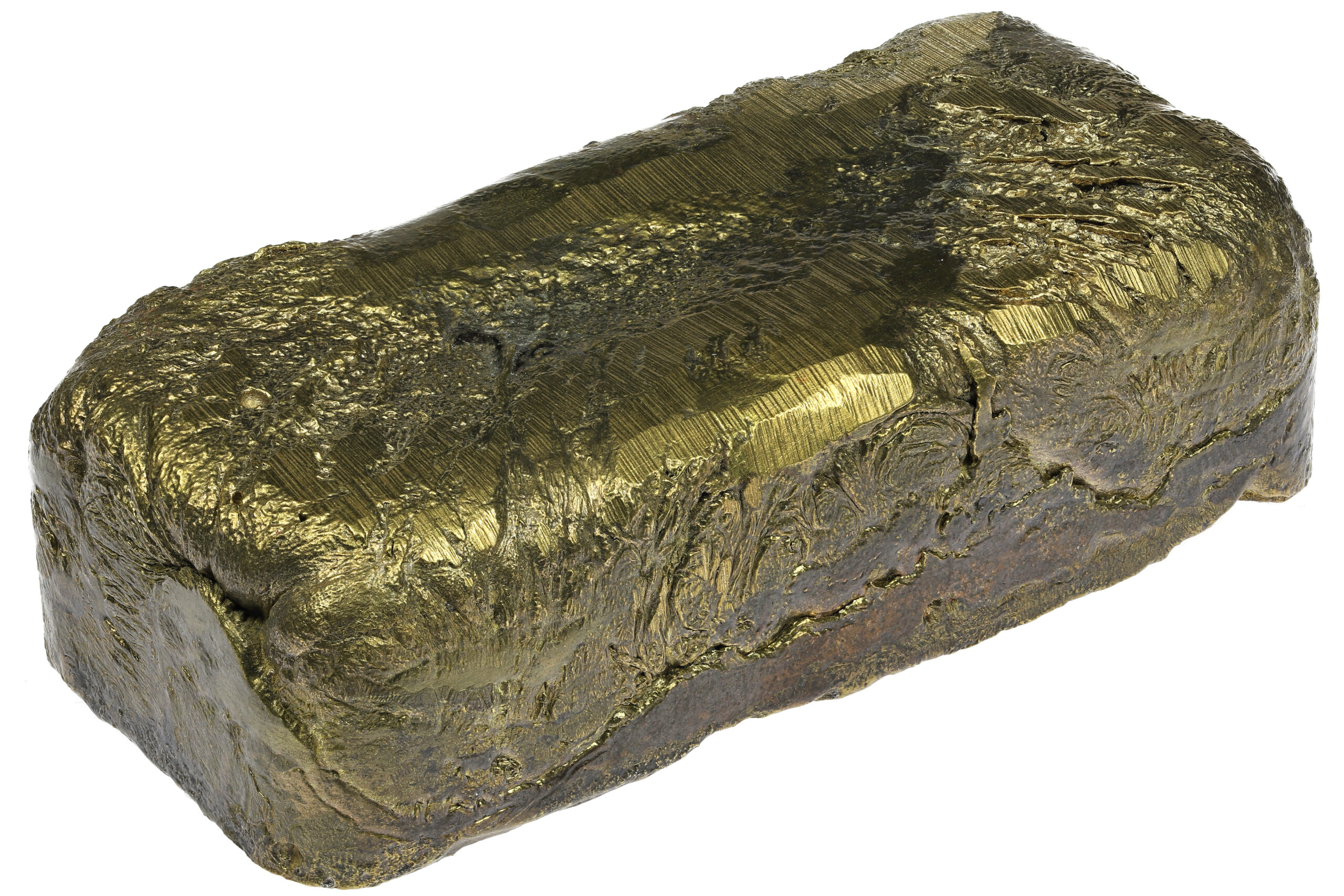

Understanding Scrap Brass

So, what exactly is scrap brass metal? In simple terms, scrap brass refers to any brass material that is no longer needed, typically from plumbing, hardware, or automotive applications. It can include:

- Old Faucets and Fixtures: Plumbing hardware that’s been replaced or upgraded during renovations.

- Brass Valves and Fittings: Components that have been removed during plumbing or HVAC work.

- Brass Scrap from Appliances: Parts from appliances that contain brass, like some kitchen or laundry appliances.

- Manufacturing Waste: Brass can be generated as scrap in industrial settings from machining processes, where excess material is removed during part fabrication.

- Automotive Components: Brass fittings and connectors found in older vehicles can also contribute to scrap brass when vehicles are decommissioned or repaired.

Types of Brass for Recycling

Brass comes in a variety of types, each with its unique qualities and recycling value. Let’s look at the different types of brass scrap you’re likely to encounter and why they matter in recycling:

- Yellow Brass

Yellow brass is probably the most familiar type. It’s that classic golden-colored metal found in everyday items like plumbing fixtures and musical instruments. With a copper content of around 60-70%, it’s popular for recycling because it’s widely available and relatively pure. - Red Brass

Ever seen a pipe fitting with a slight reddish tint? That’s likely red brass, also known as gunmetal. It’s a bit pricier in recycling since it has a higher copper content (about 85%), along with tin and lead to increase its durability. You’ll find it in heavy-duty uses like valves, marine hardware, and anything that needs to stand up to tough conditions. - Cartridge Brass

True to its name, cartridge brass is used in ammunition casings and has a mix of 70% copper and 30% zinc, making it tough but also easy to shape. It’s ideal for fasteners and shell casings, and its composition keeps it in demand with recyclers. - Admiralty Brass

Designed to handle saltwater, admiralty brass has a dash of tin added to the usual copper-zinc mix to ward off corrosion. This makes it perfect for marine uses, like condenser tubes, where durability really matters. Its corrosion resistance is a big bonus in recycling, especially if it’s in decent shape. - Naval Brass

Another type made for the high seas, naval brass is similar to admiralty brass but even tougher, thanks to its added tin content. You’ll find it in marine equipment and hardware that can take a beating from saltwater. Its durability and purity give it solid value in the scrap market.

So, when recycling brass, the cleaner and more “pure” it is (without too many added metals or contaminants), the better! Higher copper content also typically boosts the value since it means less processing for recyclers to get usable metal.

Types of Brass Found in Scrap

You might wonder—what type of brass scrap can you recycle? Here are some common types:

The Recycling Process of Scrap Brass

Recycling scrap brass combines hands-on effort with cutting-edge technology, ensuring top-notch recovery and sustainability at every step.

- You Bring It to C&D: Start the process by bringing your brass scrap to our facility. Our friendly team is ready to assist you!

- Initial Inspection and Sorting: We assess the quality and type of brass scrap.

- Cleaning and Preparation: Any non-metal attachments or contaminants are removed to enhance the value.

- Shredding and Separation: Larger pieces are shredded to facilitate the separation of different metals and materials.

- Metal Purification and Preparation: The brass is purified to meet industry standards before it’s sold to manufacturers.

- Repurposing into New Products: The recycled brass is transformed into new products, contributing to a sustainable future and reducing the need for raw materials.

Before You Bring Us Your Brass Scrap

A little preparation can significantly enhance your recycling experience. While we’re happy to accept your brass as-is, taking a moment to get it ready can streamline the process and potentially increase your payout. Here are a few simple steps to help your brass shine:

- Sort Your Brass Types: If you have different types of brass—like rods, sheets, or fittings—separating them before drop-off can speed up the recycling process and may help you secure a better price.

- Quick Clean-Up: If time permits, give your brass a quick clean. Removing any dirt or grease can enhance the value and make it easier for us to process.

- Eliminate Non-Metal Components: Check for any plastic, rubber, or other non-metal attachments. If possible, remove these extras. This not only helps us process your scrap more efficiently but could also mean more cash in your pocket.

How Scrap Metal Prices Are Set

Ever wondered why scrap metal prices fluctuate? Here’s a quick breakdown of what determines the brass scrap price:

- Type and Quality: The cleaner and purer your metal, the more it’s worth. Think of it as the VIP treatment—quality matters!

- Market Demand: Scrap prices move with the market. If demand for brass is high, scrap brass prices could skyrocket.

- Quantity: The more metal you bring in, the better your rate. Bigger hauls often mean better deals.

- Processing Costs: Sorting, cleaning, and transporting scrap take time and resources. While you get paid, these factors also play into the final price.

By following these tips and knowing how pricing works, you’ll be ready to get the most out of your brass metal recycling!